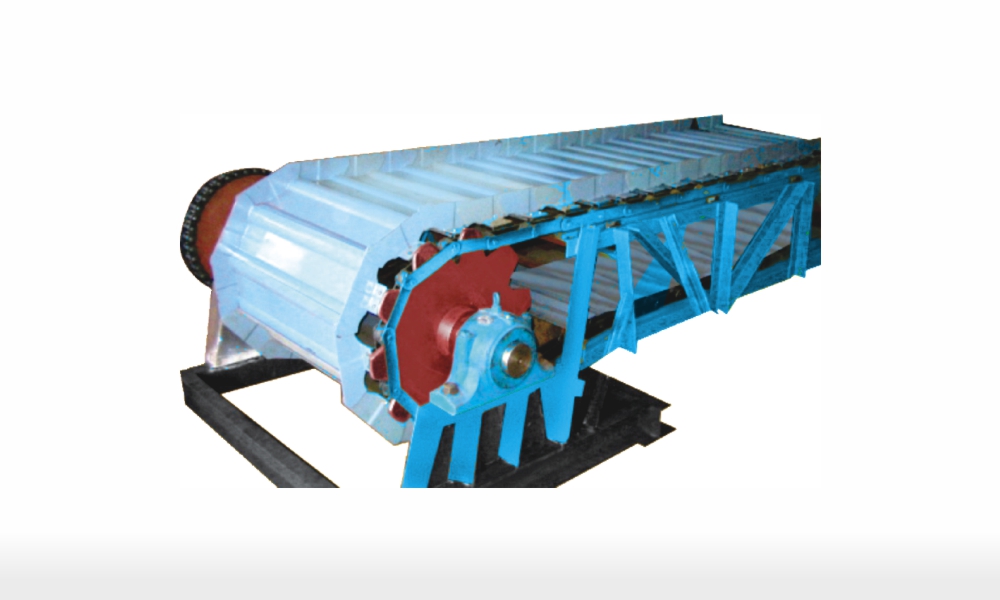

Description

SSEC Apron conveyors are specially designed for handling bulky and high-temperature castings directly from the shakeout station to fettling area.The Apron conveyors are fabricated with heavy steel sections. Pan plates that carry the castings are mounted on special chain arrangements and they run on the stringer arrangement with the help of a drive system. The drive system is driven by a special direct drive geared motor. Both ends of the conveyors are provided with heavy sprocket arrangements as drive and driven units. Tensioning units are provided to adjust the tension of the conveyor. Degating can be done on the conveyor itself because of the rugged design.

Salient Features

• Low noise level and low power usage.

• The conveyor is designed to take high impact.

• Long life as there is no relative motion between the metallic belt and handling material.

• The conveyor can be equipped with variable speed drive as an option.

• The conveyor can be provided with a hood arrangement based on the requirement.

• Less wearing parts, Hence Less maintenance.

• The conveyor is designed to take high impact.

• Long life as there is no relative motion between the metallic belt and handling material.

• The conveyor can be equipped with variable speed drive as an option.

• The conveyor can be provided with a hood arrangement based on the requirement.

• Less wearing parts, Hence Less maintenance.

Benefits

• High-temperature material handling at significant inclinations and lengths.

• Can be used as an ideal moving worktable for Runner and riser removal.

• Electric furnaces and cupolas can be charged by apron conveyors.

• Safety in handling hot castings

• Reduction in manpower

• Can be used for de-gating system

• Can be used as an ideal moving worktable for Runner and riser removal.

• Electric furnaces and cupolas can be charged by apron conveyors.

• Safety in handling hot castings

• Reduction in manpower

• Can be used for de-gating system

Contact for Technical Information

Casting Handling

Have any Questions?

Call us!

+91 4254 272165

sales@sreesakthiindia.com

Drop Us a Line

+91 4254 272165 / 292292

Call Us Now

Karamadai, Coimbatore, India

Get Direction