Description

Return Sand Temperature, after the vibratory shake out in a mechanized green sand foundry is around 200°C. In a metal-poured mould the sand temperature adjacent to the metal surface area is even higher. The quantity of heat to be removed depends on the sand to metal ratio and the holding time of metal in the mould. The return sand temperature at the inlet of the cooler is around 100°C. The sand temperature influences the quality of the mould and thus the surface finish of the casting. So, sand cooling plays a very prominent role in a foundry.

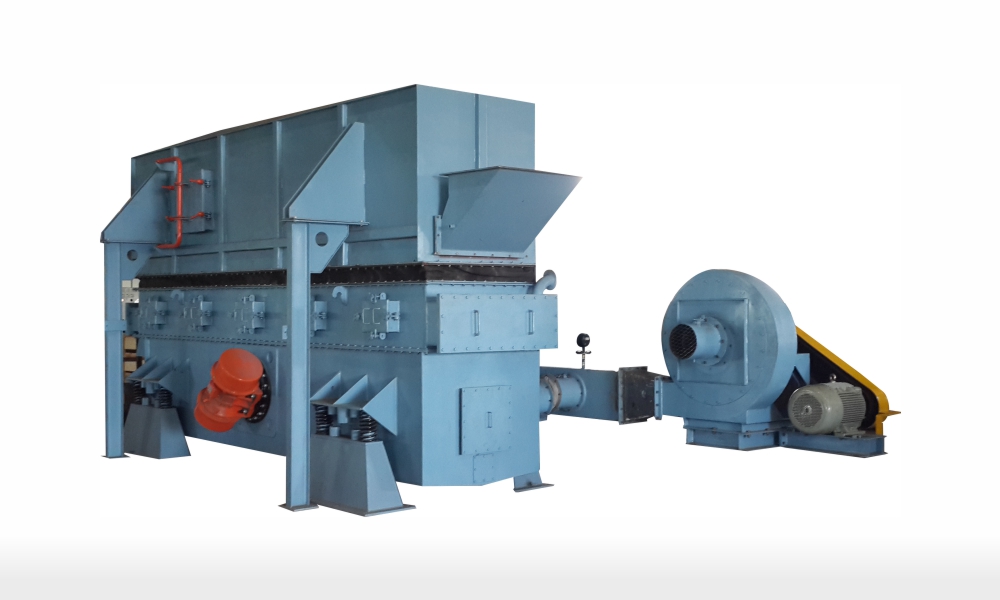

Our state-of-the-art sand cooling systems are constructed with a specially designed mesh deck and water chamber. The water chamber is built with several Stainless-steel pipes connected parallel to each other and water is circulated through them. Fins over the pipes help in heat dissipation from the sand. Also, Fresh air is blown through the perforated chamber, and at the same time water mist is sprayed over the sand bed from nozzles located in the chamber. In the Vibrating conveyor turbulence caused by the air blown ensures that sand & water mix well so that the water evaporates, and the sand is cooled.

Our state-of-the-art sand cooling systems are constructed with a specially designed mesh deck and water chamber. The water chamber is built with several Stainless-steel pipes connected parallel to each other and water is circulated through them. Fins over the pipes help in heat dissipation from the sand. Also, Fresh air is blown through the perforated chamber, and at the same time water mist is sprayed over the sand bed from nozzles located in the chamber. In the Vibrating conveyor turbulence caused by the air blown ensures that sand & water mix well so that the water evaporates, and the sand is cooled.

Sand Moistening

Sand temperature is measured at the inlet of the cooler and in the vibratory conveyor of the cooler. An electronic thermometer controls the amount of water sprayed in several steps. Depending on the values measured, spraying nozzles are engaged or disengaged. This determines the exact dosage of the water required for cooling and moistening.

Salient Features

- Cooling systems maintain a constant temperature and moisture on the return sand.

- Low maintenance because there are fewer moving parts.

- Quick cooling by double effect (water and air cooling).

- Sand movement effected by the fluidization and vibratory motion.

- Balanced draft system ensures negative pressure above the bed.

- Environment friendly.

Benefits

- Substantial reduction in rejection of castings.

- Savings in conversion cost of rejected castings.

- Substantial savings in bentonite consumption.

- Excellent surface finish of castings.

- Increased productivity.

- No oolite formation occurs in mulling.

- Continuous online use of return sand.

- Ease of maintaining permeability and hardness of the mould.

- Savings in manpower cost.

Technical Specification

MODEL | SSEC - VC20 | SSEC - VC30 | SSEC - VC40 | SSEC - VCSO |

Capacity Tons I hr | 20-25 | 30-35 | 40-45 | 50-60 |

Drive Power Kw | 2.6 x 2 | 4 x 2 | 4.3 x 2 | 4.3 x 2 |

Size Length x Width | 4000 x 1000 | 5000 x 1000 | 5000 x 1000 | 5000 x 1500 |

Fluidisation Fan Power (Kw) | 15 | 18.5 | 22 | 30 |

Contact for Technical Information

Have any Questions?

Call us!

+91 4254 272165

sales@sreesakthiindia.com

Drop Us a Line

+91 4254 272165 / 292292

Call Us Now

Karamadai, Coimbatore, India

Get Direction