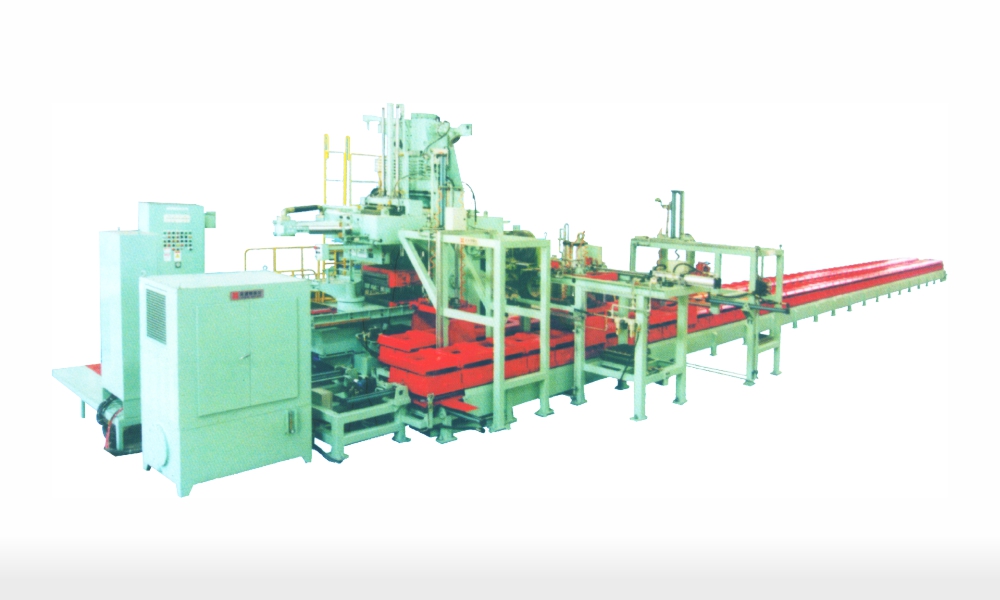

High Pressure Moulding Line - TOKYU, Japan

Description

The AMF series offers Tokyu’s next generation technology that promises high-quality castings and higher productivity. The new AMF series machines are specially designed for high-speed productivity of mould with minimal manpower. These series machines come with vertical blowing and horizontal parting mechanisms. The variable corner squeeze and combined blow mechanism assure high-quality moulding thus increasing casting productivity.

Salient Features

• As the sand shooting and squeezing are at the top of the machine, all cylinders are outside which is open which makes maintenance easier.

• The requirement of sand is not so strict (moisture, sand strength, etc.).

• Vertical sand shooting uses the gravity force hence lesser air pressure is sufficient.

• Pattern change is easy since there is no bolt fixing.

• Pouring gate position is easy to change as it can be done outside of the machine.

• Horizontal stripping with spring loading makes minimum shift in the mould. Hence after pouring the parting line has very less fins which do not need any grinding.

• Little sand fall during moulding which is easy to clean.

• Because of the structure of pins and guide slices, the mismatch is small (precision is good) AMF II, AMF IV - 0.2mm, AMF III - 0.3mm.

• Pattern plate can be made from wood. Hence the test is easy to take [lesser development time].

• Depending on the casting shape the thickness of sand can be selected accordingly which can save sand cost.

• Down sand blowing, the distance is short which is good for filling.

• The combined sand blowing has five choices, which can be selected according to the type of castings.

• Pouring cup is removed immediately after squeezing so there is no possibility of falling of loose sand into the mould.

• Mould thickness can be varied [from 3 to 5 levels] depending upon the type of castings.

• The whole machine is open structure which is convenient for inspection and maintenance.

• The requirement of sand is not so strict (moisture, sand strength, etc.).

• Vertical sand shooting uses the gravity force hence lesser air pressure is sufficient.

• Pattern change is easy since there is no bolt fixing.

• Pouring gate position is easy to change as it can be done outside of the machine.

• Horizontal stripping with spring loading makes minimum shift in the mould. Hence after pouring the parting line has very less fins which do not need any grinding.

• Little sand fall during moulding which is easy to clean.

• Because of the structure of pins and guide slices, the mismatch is small (precision is good) AMF II, AMF IV - 0.2mm, AMF III - 0.3mm.

• Pattern plate can be made from wood. Hence the test is easy to take [lesser development time].

• Depending on the casting shape the thickness of sand can be selected accordingly which can save sand cost.

• Down sand blowing, the distance is short which is good for filling.

• The combined sand blowing has five choices, which can be selected according to the type of castings.

• Pouring cup is removed immediately after squeezing so there is no possibility of falling of loose sand into the mould.

• Mould thickness can be varied [from 3 to 5 levels] depending upon the type of castings.

• The whole machine is open structure which is convenient for inspection and maintenance.

Benifits

• Patterns are cheap and can be made from wood, resin and the price will be 1/6th compared with vertical moulding machine lines.

• Because of the horizontal parting, casting product has a huge range. Therefore, the customer can produce many kinds of castings, even if it is not a huge quantity.

• Small investment which is 1/2 compared with Tight Flask moulding machine.

• Because of the horizontal parting and pouring method the yield is better.

• Consistency in mould quality.

• High productivity with low manpower.

• Because of the horizontal parting, casting product has a huge range. Therefore, the customer can produce many kinds of castings, even if it is not a huge quantity.

• Small investment which is 1/2 compared with Tight Flask moulding machine.

• Because of the horizontal parting and pouring method the yield is better.

• Consistency in mould quality.

• High productivity with low manpower.

Contact for Technical Information

Moulding

Green Sand

Have any Questions?

Call us!

+91 4254 272165

sales@sreesakthiindia.com

Drop Us a Line

+91 4254 272165 / 292292

Call Us Now

Karamadai, Coimbatore, India

Get Direction