Spinner Hanger Type Shot Blasting Machine

Description

SSEC manufactures sophisticated and flexible Monorail spinner hanger shot blasting machine with well and advanced surface cleaning technology. These machines are engineered to process heavy and intricate components for surface finish. In this series of machine single component with maximum weight of 15 Tons can be processed.

In the Monorail type Shot Blasting Machine, comes with Manual movement or Motorised movement of hangers into the Blasting cabin. The movement of hangers through the machine is achieved by a Transport system moving in intervals continuously. With the advantage of number of hangers, loading and unloading of castings becomes easy and can be carried out while the machine is in operation. The doors are provided with Hydro Pneumatic system, which makes the door to open when the cycle is completed and the hanger movement is effected by this arrangement. Until and otherwise the blasting is stopped, the door will not open and after closing of door only blasting starts, which makes safety to the working of the machine. During the blasting cycle, the hangers are placed in two positions, which makes the efficient cleaning of the casting.

The cabins are lined with high Manganese rolled steel plates are used to avoid damage to the cabin and to improve the life of the machine and reduce the maintenance cost.

In the Monorail type Shot Blasting Machine, comes with Manual movement or Motorised movement of hangers into the Blasting cabin. The movement of hangers through the machine is achieved by a Transport system moving in intervals continuously. With the advantage of number of hangers, loading and unloading of castings becomes easy and can be carried out while the machine is in operation. The doors are provided with Hydro Pneumatic system, which makes the door to open when the cycle is completed and the hanger movement is effected by this arrangement. Until and otherwise the blasting is stopped, the door will not open and after closing of door only blasting starts, which makes safety to the working of the machine. During the blasting cycle, the hangers are placed in two positions, which makes the efficient cleaning of the casting.

The cabins are lined with high Manganese rolled steel plates are used to avoid damage to the cabin and to improve the life of the machine and reduce the maintenance cost.

Salient Features

• Inner lining of cabin with high manganese steel plate improves life of the machine.

• Quick blade Change.

• Precise setting of shot stream for effective blasting.

• Dynamically balanced rotors with Direct drive mechanism

• High rate of shot through put with minimal blasting time

• Uniform shot stream.

• Exclusive wind sifting arrangement.

• Dust extraction arrangements ensures complete collection of dust particles hence leaves no dust to environment

• Quick blade Change.

• Precise setting of shot stream for effective blasting.

• Dynamically balanced rotors with Direct drive mechanism

• High rate of shot through put with minimal blasting time

• Uniform shot stream.

• Exclusive wind sifting arrangement.

• Dust extraction arrangements ensures complete collection of dust particles hence leaves no dust to environment

Benefits

- Good surface finish of the components

- Reduced shot consumption

- Reduction in man power

- Less in maintenance

- Long life of wear parts

- Safety ensured process for operator

Optional Accessories

- Fully Automatic I Semi Automatic Cycle System

- PLC Control System

- Overhead Conveyor

- Motorised Cassette Type Dust Collection

- Rubber lining of the cabin

- Magnetic Separation System

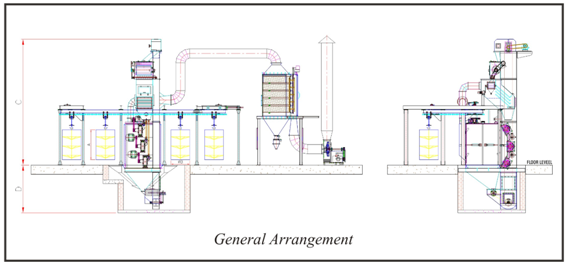

Technical specification & GA

| TYPE | SSEC 1000 | SSEC 1350 | SSEC 1800 | SSEC 2200 |

| Impeller Wheel | 2 X 300 Ø | 2 X 380 Ø | 3 X 380 Ø | 4 X 380 Ø |

| Cabin Size | 1250 X 1350 X 1400 | 1500 X 1800 X 1900 | 1900 X 2250 X 2400 | 2550 X 2800 X 3000 |

| Load carrying Capacity | 250 to 300 Kgs | 500 to 1000 Kgs | 1000 to 1500 Kgs | 2500 to 3000 Kgs |

| Impeller Horse Power | 2x 7.5 H.P | 2x 20 H.P | 3 X 20 H.P | 4 X 20 H.P |

| Maximum length of Parts can be cleaned (A) | 1000 mm | 1350 mm | 1800 mm | 2200 mm |

| Diameter of job turning circle (B) | 900 mm | 1200 mm | 1500 mm | 1800 mm |

| Cycle Time (minute) | 5 | 5 - 7 | 7 - 10 | 7 - 10 |

| Shot flow per minute | 2 X 120 Kgs | 2 X 360 Kgs | 3 X 360 Kgs | 4 X 360 kgs |

| Total Horse Power required | 23 H.P. | 55 H.P. | 85 H.P. | 115 H.P. |

| Total Height of the M/c above the ground level © | 4100 mm | 5400 mm | 6500 mm | 7500 mm |

| Height Below the ground level (D) | - 300 mm | 2150 mm | - 2425 mm | 2625 mm |

| Through put Tonnes/Hour | 1.0 - 2.0 | 1.5 5-3.0 | 3.0 - 6.0 | 5.0 - 8.0 |

Contact for Technical Information

Have any Questions?

Call us!

+91 4254 272165

sales@sreesakthiindia.com

Drop Us a Line

+91 4254 272165 / 292292

Call Us Now

Karamadai, Coimbatore, India

Get Direction