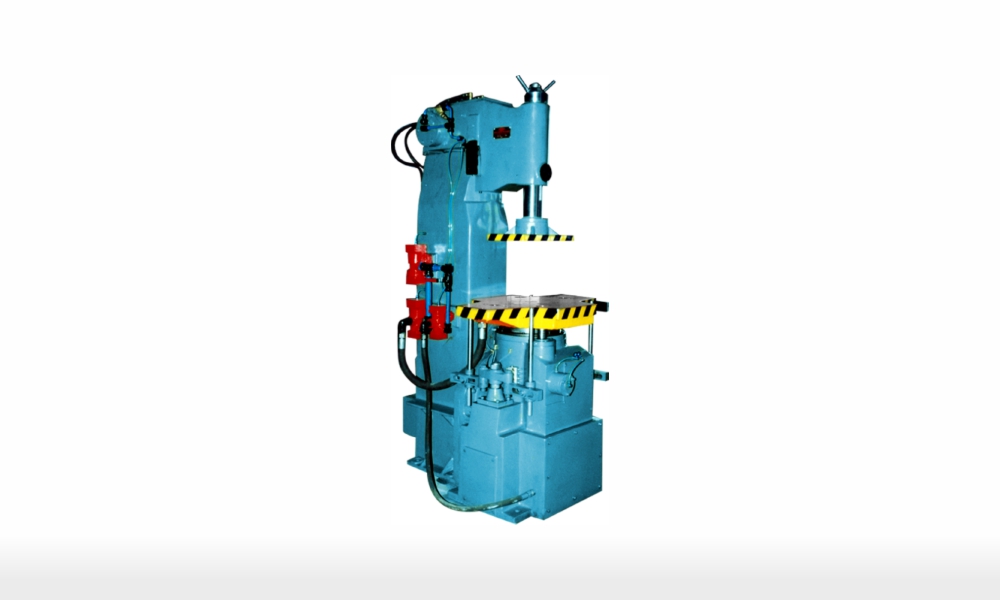

Simultaneous Jolt Squeeze Moulding Machine

Description

Engineering at its Best

• Precisely guided pin lift with Hydro pneumatics.

• Hydro - Pneumatic swing in - swing out.

• Centralized Forced lubrication on every cycle to ensure longer life of wearing parts.

• Simple pneumatic controls for easy maintenance.

• Hand wheel operated squeeze plate adjustment.

Optional Accessories

• PLC Auto Cycle Panel

• Pneumatic auto Cycle

• Pattern Shuttle arrangement

- High Productivity due to short cycle time

- Shock less high frequency low amplitude jolting

- Centralized auto lubrication during each cycle.

- Machines sturdily built as indicated by the weights.

- Mould table, Machine column ,anvil and squeeze head are made with Ductile iron casting

- Hard chrome plated guide rods & lifting rods.

- Easy access for maintenance

- Consistent high mould hardness

- Good surface finish in castings.

- Easy to operate with Pneumatic / Electro pneumatic push buttons

MODEL | SSEC | SSEC | SSEC | SSEC | SSEC |

Jolt capacity Kgs | 275 | 300 | 450 | 600 | 900 |

Static squeeze pressure Kgf | 4000 | 5000 | 8000 | 11000 | 16000 |

Dynamic squeeze pressure Kgf |

| 15000 | 24000 | 33000 | 40000 |

Table size (A x B) | 650 x 500 | 1000 x 700 | 1080 x 680 | 1200 x 800 | 1300 x 1000 |

Height between the table and squeeze plate(C) | 220 - 350 | 300 - 500 | 290 - 560 | 370 - 600 | 650 - 850 |

Ground level to m/c Bottom (H) | 650 | 450 | 600 | 720 | 900 |

Overall length (E) | 2750 | 2350 | 2700 | 3300 | 3600 |

Ground level to m/c top (F) | 1950 | 1900 | 2100 | 2580 | 2700 |

Distance between column to table centre (G) | 300 | 350 | 430 | 500 | 600 |

Pattern Draw mm | 225 | 200 | 300 | 325 | 350 |

Squeeze Stroke mm | 90 | 125 | 140 | 140 | 175 |

Air consumption per half mould (Cft) | 7.5 | 13 | 18 | 26 | 35 |

Weight of the m/c approx .kgs. | 1400 | 2500 | 4000 | 5500 | 8500 |

Contact for Technical Information

Moulding

Have any Questions?

Call us!

+91 4254 272165

sales@sreesakthiindia.com

Drop Us a Line

+91 4254 272165 / 292292

Call Us Now

Karamadai, Coimbatore, India

Get Direction